Jump to: October 13, 2025 | October 10, 2025 | October 6, 2025 | October 1, 2025 | September 25, 2025 | September 21, 2025 | September 14, 2025 | September 11, 2025

October 13, 2025

While trenching for the back wall, we discovered the largest slab yet (Joseph is uncovering it in the picture), crossing directly through the path of our trench, which was additionally obstructed with the buried remnant of a concrete terrace wall.

We were able to lever the slab out with the digging bar and lift it out, thanks for your help with that Joseph!

The wall we hit with the digging bar until it developed a weak point, and then cracked it with the sledgehammer before levering out the chunk. Heaviest concrete block yet!

All this slowed down our trenching somewhat, and we moved on to installing rebar at 4 foot intervals in the aligned block cells. While I am planting vetiver in the other cells I do not want to fully rely on an untested method. We hammered the rebar multiple feet into the ground under the wall to provide grip; reinforced cells will be filled with grout to yield monolithic support columns.

As we were installing the rebar it became clear to me that we would need an additional course of blocks along the lower walls to make the site fully level, so another block run needed soon!

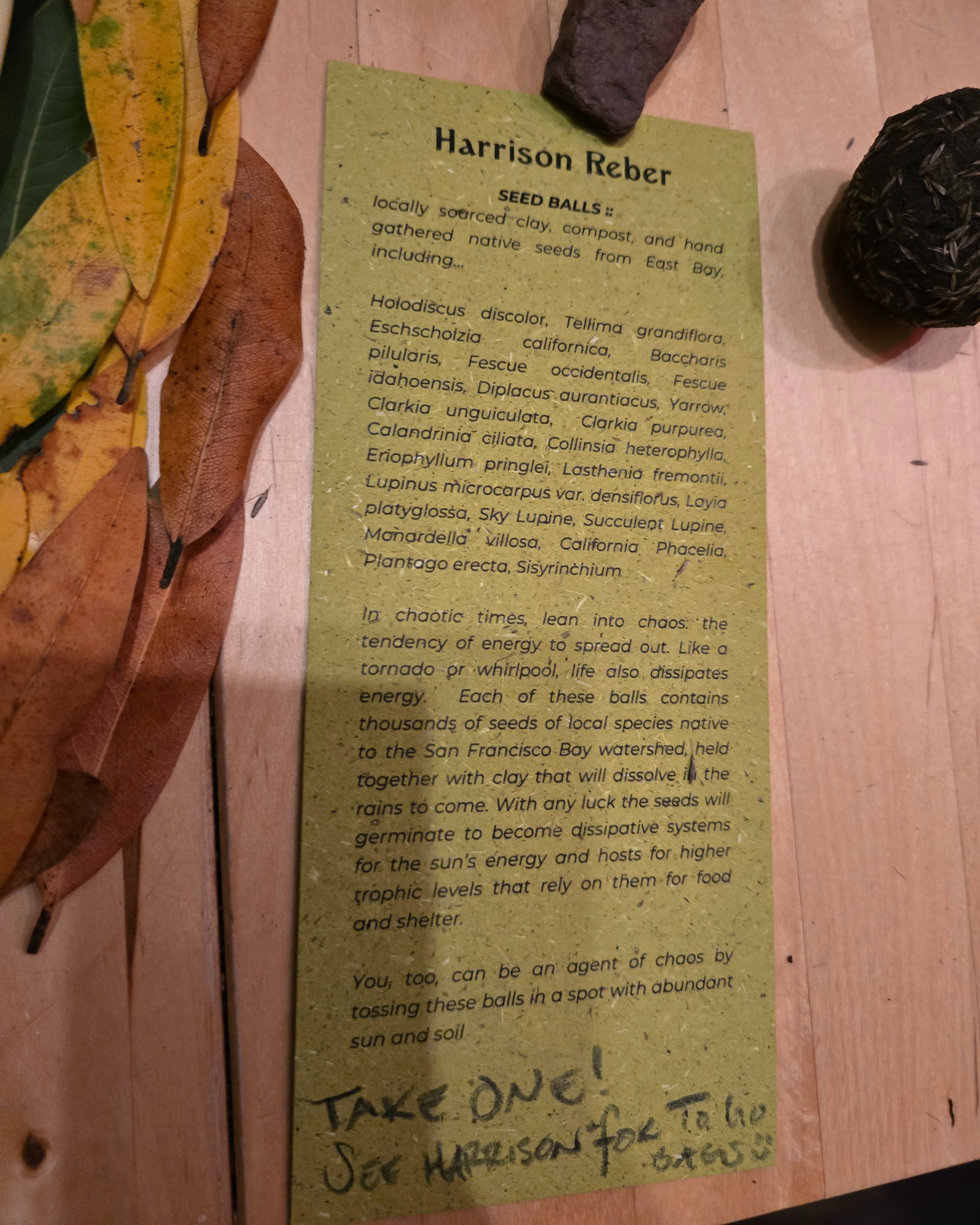

While at Gill Tract Community Farm I found Harrison (a farmer and botanist) prospecting for clay, and later he came to visit the greenhouse site and collected 5 gallons of clay from our spoil heap, with which he made balls containing the seeds of several native plants.

Seed balls provide a favorable germination environment once wet due to the hygroscopic qualities of the clay, and can be thrown long distances to enable reseeding of hard to reach areas. These we distributed at an art exhibition in San Francisco the following night.

October 10, 2025

Retaining walls need drainage on their inner base to prevent failure from hydrostatic pressure. So I got enough perforated drainpipe to lay all around the inside of the wall. The pipe will be enclosed in a sock to prevent clogging, and will burrow under the wall in the middle of the long lower side, outputting to a pile of rocks and urbanite and draining to a bioswale of wetland plants. This will also serve to progressively desalinate the soil surrounding the tamarisk. Because I will be watering plants on greenhouse benches, and the excess will drain through the floor, it is especially important to provide good drainage.

Thanks Nick for funding and helping procure another load of blocks, with which the third corner is turned!

October 6, 2025

With more blocks and gravel, and much appreciated help from Joseph, Tyrel, and Slothy (seen in-block), we leveled the trench for the long wall, and laid the first courses of blocks. In the process we uncovered slabs and terrace walls from a 1920s garden that had been covered with rocky fill. This required use of pick and sledge hammer to bring below the level of the wall. Among the rocks was an undamaged embossed glass bottle of Hines Honey and Almond Cream of 20s vintage. Ingredients beeswax, borax, alcohol, and oil of bitter almond!

Rooting continues at a rapid clip. Little rain forecast in the next week.

October 1, 2025

Another batch of blocks and the front corner is turned! Also we dug the trench to the back corner and moisture conditioned the clay, giving it a good soaking to reduce later expansion due to rain after the wall is finished.

September 25, 2025

The lower wall is almost complete!

Thank you Joseph Haddad from Counterculture Labs' Open Insulin Project for your help digging and leveling the trench, and placing the blocks.

The lower wall must be strong because it holds back the most hillside. I am going to fill the cells in the blocks with soil and plant vetiver in them. The vetiver will root down through the blocks into the hillside and become stronger over time.

Next we will be raking the spoil heap back and digging the trenches for the long lower wall, and a short back wall, for which I will need another 40 or so blocks.

I am hopeful that the trenches will produce enough rocky clay to fill the pad to a suitable level without needing a large quantity of drain rock.

Meanwhile our 200 indoor cuttings are rooting, adding some urgency to get this finished.

Help me finance more blocks and get this greenhouse finished before the rains!

September 21, 2025

Thank you all for your continued support!

I finished clearing the site and surroundings of biomass, in the process accumulating now around 120 cubic feet. Main species removed in this last batch are pokeweed and ivy. I decided that, given the large volume, the conical kiln options I had researched do not have sufficient throughput and are not cost effective, so I will instead dig a conical burn pit and make terra preta the old school way.

In the process of cutting back a large tamarisk shrub (Tamarix ramosissima), I discovered it to be heavily infested with the tamarisk leaf hopper. This and the fact that much of the french broom I cut was being actively consumed by california tent maker caterpillars was a heartening observation.

After clearing the site, I found buried paving slabs forming a pathway, which I excavated up to the position of the door (marked by rake in the picture). I then continued to follow it and dug it out up to the upper retaining wall.

Partially buried in the tamarisk thicket were large cinderblock corner pieces on top of poured concrete foundation piers, from some prior structure on the site. These will be very useful as corner foundations so I dug them out and rolled them upslope to their approximate positions.

Next task is levelling, and to do that I need to build a retaining wall on the lower level. More updates on this soon!

September 14, 2025

Thank you everyone!

With your help I was able to get a wood chipper and shred the pile of biomass resulting from clearing the greenhouse site. Species present include french broom, cotoneaster, pokeweed, tamarisk, redwood, date palm, wild oats, ripgut brome and red pepper tree.

This produced a 12'X4'X16" deep pile of mulch, or 64 cubic feet. At a density of 4.8oz/l this is a mass of 544lbs, or 247kg.

Roughly half of this consists of dry grasses and branches, the other half is fresh woody vegetation, so around 1/4 of this mass is water, giving 185kg of dry biomass. At average proportions, this contains 93kg of carbon.

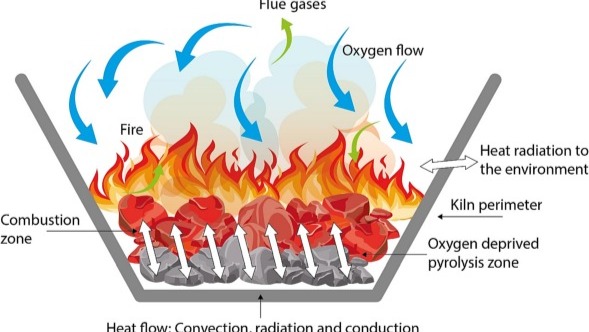

The best way to permanently fix as high a proportion of this carbon as possible is to convert it to its elemental form through the action of heat in the absence of oxygen, this will convert all substances other than carbon into gases that will boil from the wood chips and in their burning provide heat to sustain the process.

This is called pyrolysis, or dry distillation, and creates biochar as an output. Biochar is an excellent soil amendment, regulating pH, retaining nutrients, and improving soil structure. As elemental carbon, it is mostly inert from a biological and chemical perspective, and so the carbon it contains is unlikely to return to the atmosphere in the next 1000 years at least.

To make char, heat has to be applied in an oxygen deprived environment. The method usually used is the Top Lit Updraft Gasifier, consisting of 2 nested metal containers and a stove pipe. The drawbacks of this method are that it is a batch process and does not scale smoothly, while also sacrificing a portion of the biomass as fuel. I am interested in testing a different method, a conical kiln based on Japanese charcoal manufacturing methods.

Reported efficicency ranges between 25 and 50%. Another $400 will enable me to get a conical kiln, an essential piece of equipment for the nonprofit which will be used heavily, and will permanently remove between 24 and 47kg of carbon from the atmosphere while producing a soil amendment to grow more super aspens! All efficiency data will be recorded.

This also represents a small scale test of the integrated coppicing and char production system that will be deployed on planting sites.

September 11, 2025

Greenhouse site measured and marked out, mown and weed-eaten, and resultant biomass raked and heaped. I'm keeping the heaps moist to encourage decay and produce compost for propagation, need to get high temps in the center of the pile to help kill any stray french broom seeds.

Site is cleared of broom and pokeweed; there were some real big roots! Next is leveling and I will need pressure treated 4X4 to frame plus drain rock for the floor.

With the site prepared, I also propagated 200 cuttings from my indoor mothers (thanks for your help Elysha!!), and installed a light in my rooting window to extend the photoperiod to 16/8 to enable rooting to continue in winter.

Got the first bulb for my greenhouse photoperiod extension lighting. Need 3 more.

In process of acquiring an electric wood chipper to reduce the particle size of my biomass pile. I'm avoiding using city compost as far as possible to retain carbon within the system.